Over recent years it became clear to the

Government Printing Works of South Africa (GPW) that more and more security

features needed to be applied to more applications. Though GPW already have

substantial amount of digital solutions for security printing, the demand to

add these solutions onto current web printing presses had become a must. The

key however was that production speeds must not be compromised.

GPW issued two tenders for retrofit

solutions onto existing and new web printing presses to add variable security printing

features to the printed media.

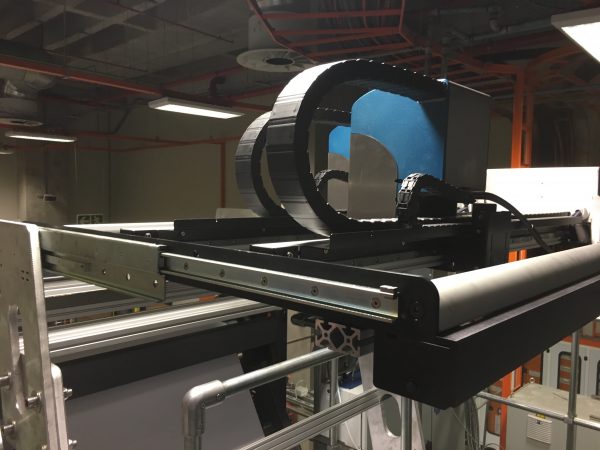

For the first of these tenders , Industrial

Inkjet Ltd (IIJ) partnered with Dutch press supplier DG Press, to add variable

data as a retrofit system to the new Vision Press for production speeds of over

200 m/min. IIJ supplied a two-step solution as part of the partnership, inline

variable data security code printed by an IIJ MonoPrint 520HiQ print engine and

an offline verification system.

The inline IIJ print engine adds various codes to the printed media at high speeds and then printed media can be verified and inspected with the offline verification system. IIJ utilised the expertise of Lake Imaging Systems to supply the high-speed camera verification system with interface IIJ print system. The camera system verifies the data printed, checking data readability and comparing it to the data file, any incorrect data will then be voided. Another remarkable feature supplied by IIJ is to record on the media a time date stamp as well responsible operator which in turn will help GPW to trace back any issues that might have arisen during the original inline print process. This solution has put GPW in a position to record all data printed with the IIJ print solution and also ensure that all documents that leave GPW are correct and recorded.

For the second tender, IIJ was asked to design a system for a unique application where the requirement was that it needed to be installed on a Man Roland Uniset Press. The application would print variable data, standard black codes as well variable data printed in covert ink only visible under UV lighting. These codes or data were required at speeds in excess of 200 m/min. The IIJ print engine and adaptor had to be designed so as not to interfere with any of the automation factors of the Man Roland Uniset Press. This project has now been completed, allowing GPW to produce any form of variable UV invisible features on any of their documents printed on the Uniset Press.

Quote from GPW: “IIJ have been able to

provide a suitable solution for the further growth of The Government Printing

Works whereby additional security has become more and more the requirement. The

flexibility and ease of use has made the transition easy for the employees”

IIJ manufactures a range of compact inkjet print

engines from 72mm to 594mm, from monochrome to full colour, 360 dpi, 600 or

720dpi and with the capability of production speeds from 54m/min to 200m/min.

For an almost limitless range of applications. Why not visit the Print Engines

page on our website: www.industrialij.com/products/print-engines/