For those looking for short

run label solutions, digital technologies have always been attractive. Both

toner and inkjet solutions have long heralded a digital revolution, but whilst

it is now common place it can never replace analogue technologies, only enhance

and improve it. That’s why at IIJ we like to refer to a digital evolution

instead.

Hybrid technologies are now in

vogue, but are they really the ideal solution and the answer to all the

applications? As with everything it depends on your circumstances.

There are several things to

consider. Firstly, the kind of work that is needed. If you are simply producing

coloured labels with minimum finishing requirements, such as die cutting and

lamination, then maybe an offline or nearline digital solution works. Although

you still may not benefit from reduced stock levels as the digital rolls need

to be stored prior to finishing. If you are producing complex labels that need

additional processes such as low cost flexo background and spot colours,

foiling, varnishing, embossing etc then an on press inline solution is the

perfect way. Putting one of our ColourPrint HiQ modules onto an existing flexo

press gives the user the power to include variable high resolution colour

images and text on multi process labels.

Secondly material workflow and

space requirements are important. For a small label company, adding another

piece of standalone hardware for near line production can be problematic and

lead to additional costs of ownership. There is the extra space, services,

staff, and storage of WIP etc. This is where hybrid solutions score big.

Especially solutions that do not require extensive surgery on the press or

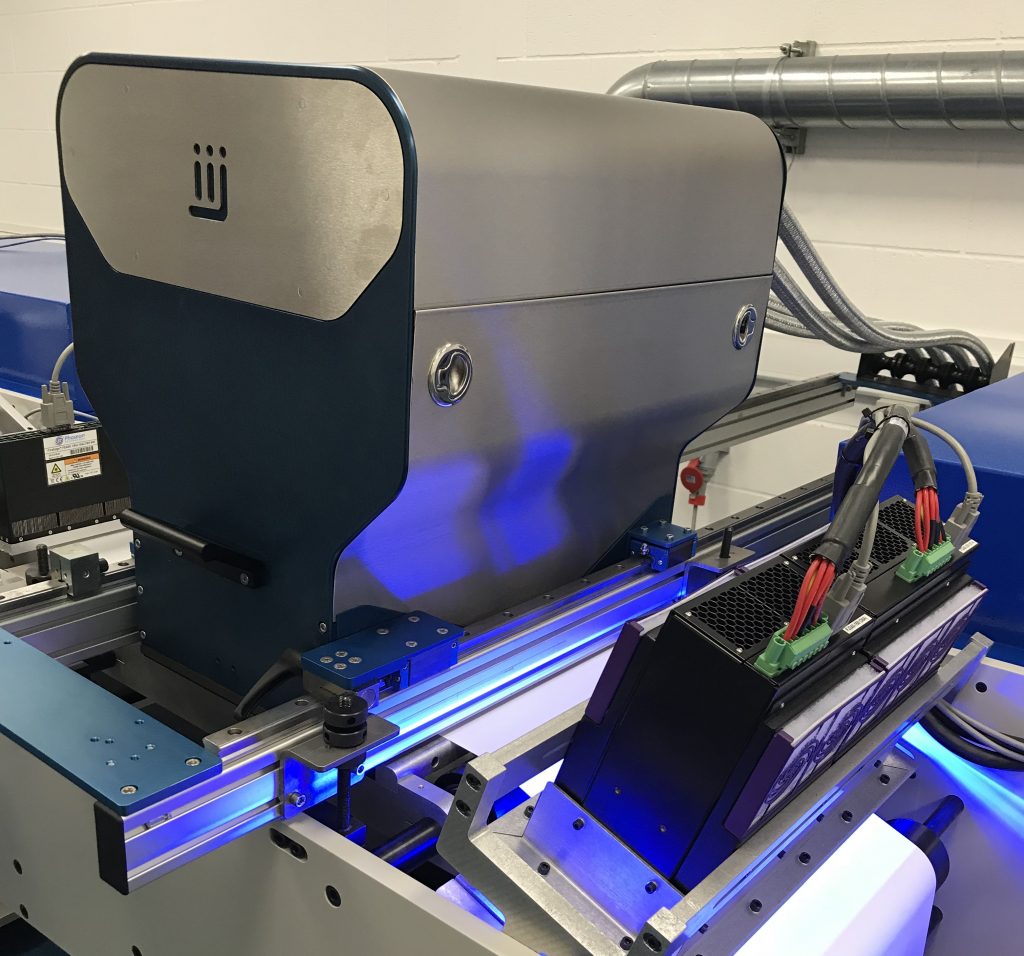

require the press to be extended. Thanks to the use of Konica Minolta’s

extremely compact high resolution KM1800i printheads, IIJ’s in-line inkjet

modules are some of the most compact on the market. This allows high quality

digital label capabilities to be added to an existing press, without the need

to remove multiple flexo stations, and also makes it easier for them to be

added to older equipment than a system with a longer print station. The compact

footprint added to the use of high efficiency LED curing allows the system to

be used exactly when and where it’s needed, especially when used on a rail

mounted press adaptor.

The third consideration is the

label material itself. Many inkjet label systems need specific label stocks

that are firstly more expensive than flexo stocks, but also do not always lend

themselves to some of the additional processes. With an on press solution, low

cost primers can be added in line, so standard stocks can be utilised, saving

money and reducing stock inventory.

Finally, production speeds.

The press speed is governed by the slowest process, and for a long time inkjet

solutions have been offered at between 25 to 50 m/minute. This then gives an

issue for in line production as it reduces production speed, undermining the

value add of the digital solution. In this scenario, off line or near line

solutions look more attractive. But what if the inkjet solution is run at 80 to

100 m/min or even 200m/min for monochrome variable data? Then the on press

inkjet solution is no longer the limiting point. IIJ label modules typically

operate at 80 to 100m per minute, and for text and variable data, speeds from

100 to 200m per minute, so they can hit this requirement, and then the world of

hybrid labels is much wider.

So are they truly the best of

both worlds, well at IIJ we have been supplying hybrid technologies since 2010

and we believe that actually by evolving the analogue label production process

through innovative use of inkjet, the result is much more powerful that the

separate processes alone. We pride ourselves on delivering reliable solutions,

tailored to our customers exacting requirements. Short run colour self-adhesive

labels can be perfectly produced using IIJ’s high resolution ColourPrint HiQ

engines suitable for premium labels used in the food and beverage sector,

personal care such as shampoo and cosmetics, nutraceutical labelling, and

labels for consumer goods. For industrial labels, coding and marking labels,

including security labels, the MonoPrint series really hits the spot.

Clothing swing tags and RFID

labels are also easily produced by combining our outstanding variable data

capabilities with our latest colour management capabilities, giving accurate

spot colour identifiers required in this market. If migration and set off

concerns exist for an application, IIJ also has a range of solutions using Low

Migration inks, so pretty much whatever you are looking for in an inkjet

labelling solution, IIJ can deliver. Not just for labels; The same concept

works for flexible packaging, blister foil, commercial print and even

corrugated board!

This year LabelExpo Europe will be more digital

than ever as the market demands ever shorter runs and variable content. IIJ

will be there, in Hall 6, Stand 6D11, to answer your real production needs. We

have been at this a long time, and our equipment is always improving and

evolving, so even if you think you know our offering, think again, we believe

you’ll be pleasantly surprised.