The latest in compact industrial printing from IIJ

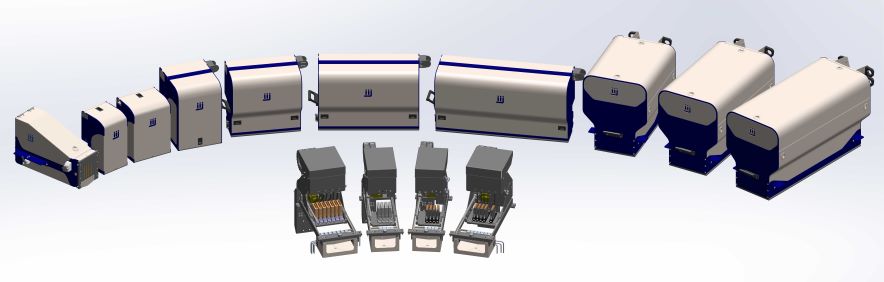

This month IIJ will deliver its first MonoPrint 371HiQ print Engine built to its new compact monorail design. This completes the process of updating of the entire range of IIJ’s popular compact inkjet print modules, referred to as Print Engines. With this addition, it takes the list of possible configurations to 55 models, and when ink options are considered such as low migration UV, high opacity white, covert security inks, spot colours, waterbased packaging inks etc, the list stretches out to over 250 options.

Ever since the conception of the Print Engine concept for Drupa 2008, IIJ has been constantly improving and extending it. The range has undergone some significant changes over the years. Originally utilising Konica Minolta KM512 printheads, the systems quickly moved to using the KM1204. Following the launch of the high speed KM1024i series in 2012, the entire range adopted this much more productive technology. Since 2015 the range has been even further extended to include the truly impressive KM1800i printhead.

IIJ Print Engine range

IIJ Print Engine range

IIJ has always strived to maximise the capabilities of the Konica Minolta technology. The first IIJ Print Engine had a maximum speed of only 18m/min, but within a couple of years the first high speed monochrome unit was produced running at 80m/min. When the KM1024i series became available, 80m/min was a standard, but by innovative design and thorough development, IIJ used this technology to produce their 300m/min coding system the MonoPrint XPi in 2016.

The original MonoPrint HiQ series, showcased at LabelExpo in 2015, wowed the crowds with high quality print at 100m/min. But again, IIJ didn’t stop there, by again using the full scope of the KM1800i printhead’s capabilities, the product is now working at 200m/min in various customer sites worldwide. This can be seen in action here: MP371HiQ . The process colour version, the ColourPrintHiQ series, launched at LabelExpo 2017, is already proving very popular in the label, packaging and security markets as it’s high productivity and small footprint make it perfect for adding to existing printing equipment to give hybrid functionality, effectively and economically.

Over the last 2 years, IIJ has been increasing the functionality and ergonomics of the systems, making them even more desirable products and the delivery of the latest product completes the initial phase of that activity.

Following, this IIJ will add its new automatic head cleaning system to the range as well as further software enhancements and as always more inks and more applications.

So, watch this space for new additions to the IIJ product family, as it is always growing to ensure that IIJ delivers what the industrial printing market needs.